At AWD, we’re looking through our archives at some of our most memorable projects, and this week we’re shining the spotlight on our structural surveys. We provide comprehensive structural assessments on a wide range of permanent and temporary structures, including global stability checks, condition reports and feasibility assessments. Read on to learn about our structural survey project for Koppers Inc, from 2012.

Global firm Koppers Inc are world leaders in the manufacture of products and services for infrastructure projects. At their Tar distillation plant in Port Clarence, Middlesborough, a shiploader is used to load boats with coal pitch tar pellets from a concrete wharf. Koppers Inc approached AWD to provide a full condition report on the structure of the existing shiploader, as well as a feasibility assessment for a proposed extension to the shiploader, to allow a larger size of boat to be loaded at the facility.

The shiploader was made from standard steel columns and beam sections, with plate girders and web stiffeners situated throughout the structure to provide strength and stability. The arm of the loader was formed from a box truss which used a conveyor belt for the transportation of materials, which were transferred to the boats below via a chute hung from the end of the arm.

Our condition report was completed on-site with our engineers performing a detailed inspection of the existing shiploader, analysing the structure for any non-standard elements such as corrosion in the steelwork and bolts or modifications to the original design. As with all our surveys, our engineers provided detailed recommendations to our client based on our findings to highlight sections requiring protection or replacement to maintain the integrity of the structure for further use, such as repairing surface corrosion and replacing delaminated steel sections which had been eroded through normal wear and tear.

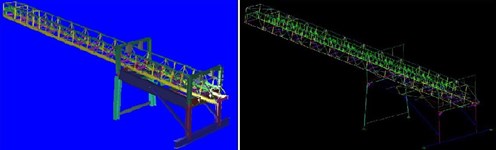

After our initial condition survey, our engineers performed a feasibility survey to determine whether the existing structure had any additional strength capacity to support a 4m extension to the arm box truss. Using STRAP analysis software, our structural engineers completed a global analysis on the structure, producing a 3D model which we manipulated to determine how the structure would respond when exposed to the additional load of the extended arm. We also incorporated local working and storm wind loads to our assessment to account for environmental and other external factors which might affect the stability of the extended structure.

After comprehensive structural analysis we confirmed the extension was feasible, providing stress loads for all members in the structure to verify our findings. As we take a holistic approach to all our projects, we also provided recommendations to our client to highlight other considerations, such as testing of the concrete wharf, which may be required prior to the construction of the extension.

Our work for Koppers Inc is a typical example of the type of comprehensive structural surveys that our expert engineers offer, and we believe our industry leading expertise in this area allow us to provide fast, simple and effective service for our clients.

Contact us at [email protected] or call us on 01563 594621 to find out more about or survey services, or read about some of our other structural projects here.